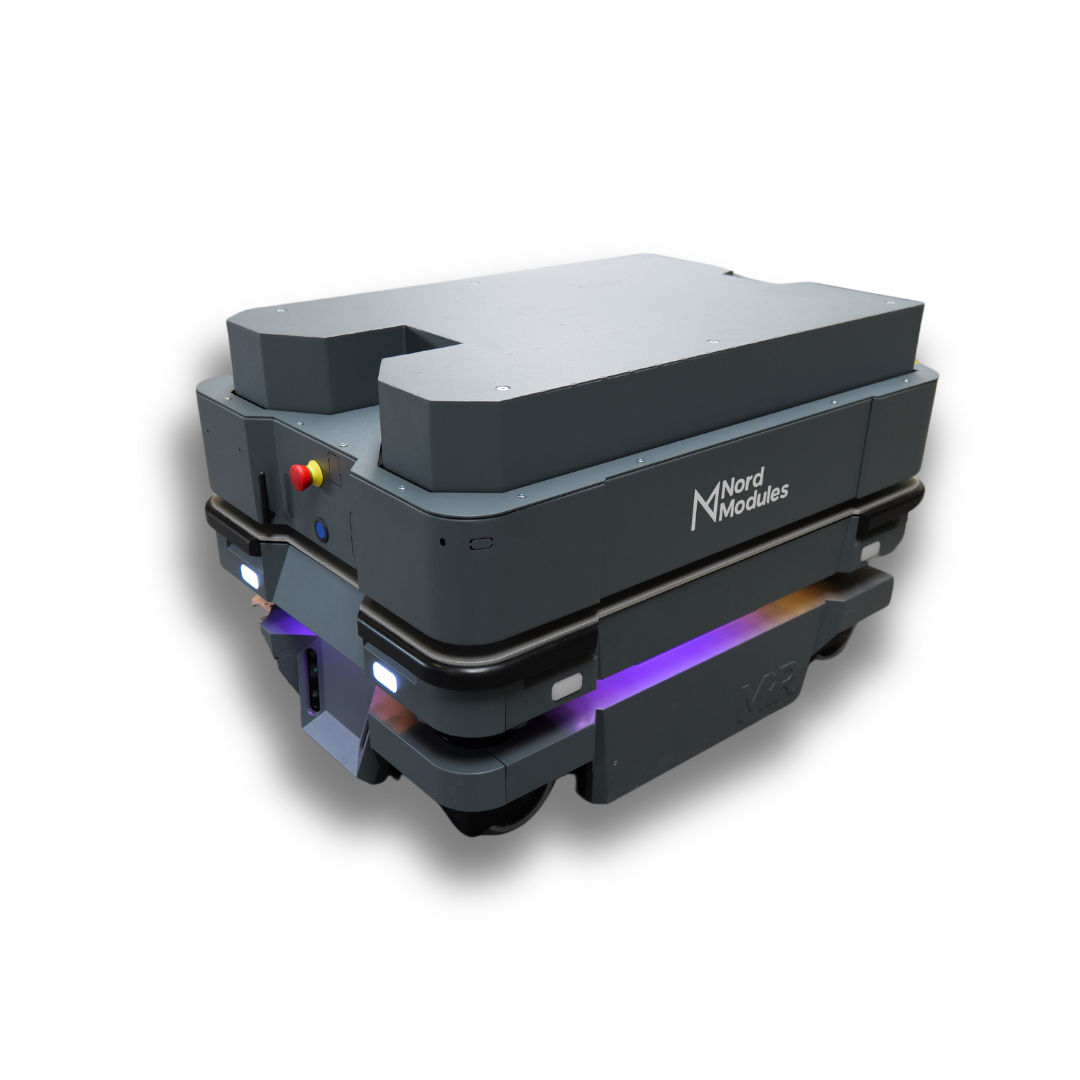

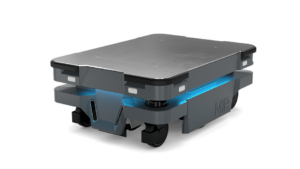

QL220-510-MiR

Robot compatibility: MiR250

Nord Modules compatibility: Basic Gate, Wheel Gate, Shelf Cart, Cobot Tower

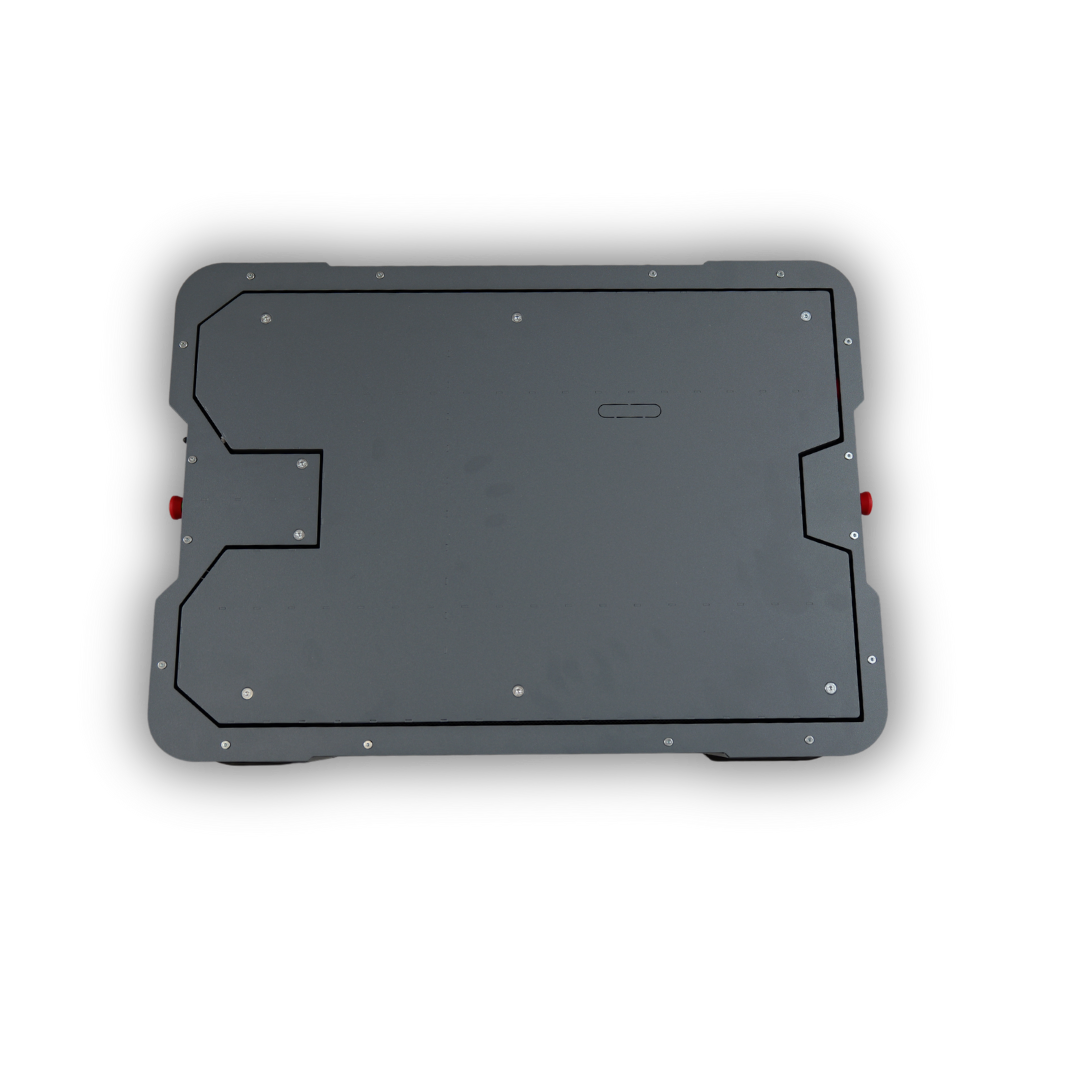

Dimensions (LWH): 794 x 560 x 198.5/278.5 mm | 31″ x 22″ x 7.81/10.96″

Handling capacity: 220 kg | 551 lbs

Lifting capacity: 0-80 mm | 0-3.15″

Transport area: 780 x 560 mm | 30.7” x 22.05”

Weight: 30 kg | 66 lbs

Color: RAL 7011

Description

The Quick Lift 220-510 is our newest solution designed specifically for the MiR250 robot! Engineered for maximum flexibility and security, the Quick Lift 220-510 is perfect for handling pallets, crates, racks, and more, ensuring seamless transitions between different load types with minimal adjustments.

The Quick Lift 220-510, along with our other solution for the MiR250, the Quick Mover 220, can effortlessly transform into one another. This innovative feature ensures you’re equipped to manage a wide range of payloads and shapes, providing a 2-in-1 solution that enhances your automation capabilities.

Your key benefits:

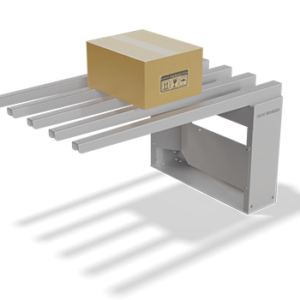

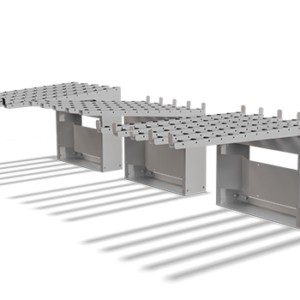

- Simple set up and installation – can be up and running within a few hours, thereby providing a complete and flexible solution with the gate modules and carts.

- Flexible standard product designed to simply adjust to specialized work processes which form efficient automation of internal transportation.

- Requires only minor adjustments for different material handling tasks, enhancing operational efficiency.

- Reliable and cost-efficient – The Quick Lift reduces costs and increases productivity.

Optional Add-ons:

- Payload detection sensor that detects whether there is an object on the gate or on the Quick Lift.

- Side sensor for compatibility with On-The-Fly Gate.

- Code scanner for QR or barcodes.

- Payload measurement kit that weighs the load being transported.

- Stack light tower that gives extra visibility.

- Blue light signal interface.