Conveyor systems are an essential part of many manufacturing and distribution operations – they increase efficiency, reduce labor costs, and improve safety, to name a few. However, with the advancement of technology, Autonomous Mobile Robots (AMRs) have emerged as a new alternative to traditional conveyor systems.

Although both approaches differ in engineering and functionality, both have the same end goal – a reliable, stable, and quick movement of products. So how do AMRs stack up against traditional conveyor systems? Where does one solution shine, while another does better in a different application?

In this article, we will compare traditional conveyor systems to AMR conveyors, highlighting the benefits and downsides of both and how to pick the one that is perfect for your needs.

Traditional Conveyor Systems

A traditional conveyor system consists of a series of rollers or belts that transport goods along a fixed path. They are generally powered by an electric motor or a gravity system and are available in a variety of sizes and configurations to suit different applications. Conveyor systems have really proved the test of time as being the main system of reliable and quick movement in a warehouse. They are an excellent choice for moving large volumes of goods over long distances in a straight line.

Benefits

- They are ideal for transporting heavy loads over long distances.

- They are simple to install and operate.

- They require minimal maintenance.

- They can be easily automated.

- They can handle the broadest range of loads and types.

Downsides

- They have a fixed path, making them inflexible.

- They require a large amount of space, limiting their application in areas with space constraints.

- They cannot adapt to changes in the production process, making them less versatile.

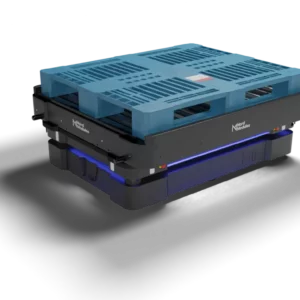

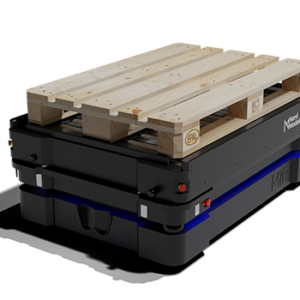

AMR Conveyors

AMR conveyors are a new type of material handling solution that uses Autonomous Mobile Robots (AMRs) to transport goods. AMRs are self-driving robots that can navigate around obstacles and map out their surroundings using sensors and cameras. AMR conveyors allow for more flexibility in moving goods as they can change direction and path without requiring any additional infrastructure or modifications. They are usually used for order fulfilment of relatively lighter, more unitized loads.

Benefits

- They can navigate through a warehouse without the need for fixed infrastructure like conveyor belts or guide rails.

- They are more flexible and adaptable, allowing them to change their route and direction quickly.

- They require less space compared to traditional conveyor systems, making them ideal for areas with space constraints.

- They can handle a wide range of payloads and can be customized to suit specific applications.

- They can be integrated with warehouse management systems to streamline the entire process.

- They are built for higher accuracy and flexible control.

Downsides

- They are more expensive than traditional conveyor systems.

- They require more frequent maintenance as they have more moving parts.

- They have limited payload capacity compared to traditional conveyor systems.

How to choose the perfect solution

There are many different types of conveyor systems and choosing the right conveyor solution for your business depends on several factors, including the type of goods you need to transport, the layout of your facility, and the volume of goods you need to move. If you have a large facility with a high volume of goods to transport over long distances, a traditional conveyor system may be the best choice. On the other hand, if you have a smaller facility with limited space, and need a more versatile and flexible solution, an AMR conveyor system may be more suitable.

Both traditional conveyor systems and AMR conveyors have their own benefits and downsides. However, with the increasing demand for flexibility and adaptability in material handling, AMR conveyors have emerged as a better alternative. They are more versatile, require less space, and can be customized to suit specific applications. If you are looking for flexible conveyor systems that can keep up with the changing demands of your business, an AMR conveyor system may be the perfect solution for you.